43 thermal transfer labels definition

Direct Thermal vs Thermal Transfer Labels - Barcode Blog 6 Apr 2022 — Thermal transfer (TT) printing requires a ribbon to print. The ribbon acts as a buffer between the print head and the label material. As the ... Understanding Thermal Labels: Direct Thermal vs. Thermal Transfer Thermal transfer paper labels are a good choice where direct thermal is not suitable or the print quality of the ribbon is preferred. Thermal transfer synthetic labels are suitable for outdoor labelling and applications where high levels of moisture or scuffing are expected. Examples: Laboratory labels; Inventory identification labels

Durable Labels for Extreme Hot & Cold Temperatures Our labels are compatible with the following hot applications. Identification labels - Keep labels intact on tools and products that are used in hot water baths, autoclaves, and more.; Barcode labels - Ensure products are scannable at their final destination with heat-proof barcode labels.; Pump and valve labels - Mark water mains, chemical valves, and other pumps to keep communities ...

Thermal transfer labels definition

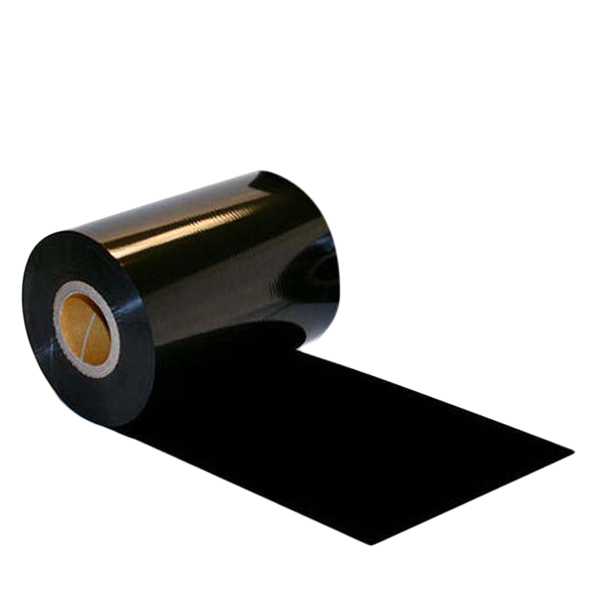

Thermal transfer | inkanto by ARMOR-IIMAK Thermal Transfer printing is a simple, performing and competitive printing technology that enables to print all types of labels and flexible packaging.. Definition What is Thermal Transfer Printing ? Applications Thermal Transfer: barcode and packaging printing Sustainable Performance Thermal Transfer Sustainable Performance Industrial printers Définition of thermal transfer printing | inkanto by ARMOR-IIMAK Thermal Transfer is the world's most popular printing technology for the marking of variable information on labels and flexible packaging : barcodes printing, logos, text, expiry dates and batch numbers. Direct Thermal vs Thermal Transfer Printer | Direct Thermal Transfer Labels What are Thermal Transfer Labels? These thermal transfer printer labels require a ribbon when printing. Both the labels and the ribbon feed through the printer, and the printer applies heat to the ribbon to transfer the wax and resin onto the label (hence the term thermal transfer printer).

Thermal transfer labels definition. Label Terminology | A to Z Label Terms To Know - Whitlam Thermal Transfer Technology: Utilizes a ribbon and matching label, ticket or tag stock material to transfer an image onto the label material. For the best solution with long life requirements or harsh environments, ask one of our experts to recommend an optimal thermal transfer ribbon. Direct Thermal vs. Thermal Transfer - Brother Mobile Solutions Thermal transfer printers use ribbons made of wax or resin-based ink that melt onto the printing media (e.g., a label or similar) and create a long-lasting, ... Direct Thermal and Thermal Transfer Printing | Zebra Thermal Transfer Printing. Thermal transfer printed labels are easily identified by the crisp, often glossy, printed surface. The clarity is achieved by using a thin ribbon roll that when heated by the printhead melts onto the label to form the image. The ink is absorbed so that the image becomes part of the media. Understanding Labels: Thermal Transfer vs. Direct Thermal During thermal transfer printing, the ribbon is run between the label and the printhead, with the coated side of the ribbon facing the label. As the ribbon and ...

What is thermal transfer printer? - Definition from WhatIs.com Thermal transfer printers are popular for printing bar codes, labels, price tags, and other specialty print jobs. There are two types of thermal transfer printers: direct thermal and thermal wax transfer. Direct thermal: The direct thermal printer prints the image by burning dots onto coated paper as it passes over the heated printhead. Direct thermal printers do not use ribbons. Fanfold - Thermal Transfer Labels - Labelsontime Buy fanfold Labels for thermal transfer printing. Our collection of thermal labels for transfer printing in fanfold stacks is extensive. Most sizes with have a choice of both perforated and nonperforated and come with a permanent acylic adhesive. A variety of materials, adhesives and color thermal labels are available on 3" cores for your ... What are Thermal Labels? | Zebra Thermal labels use heat to create an image. Thermal transfer uses a thermal ribbon where heat from the printhead releases the ribbon attaching it to the label surface. Direct thermal images are created when heat from the printhead causes components on the label surface to mix causing them to (usually) turn black. A label is a label right? Wrong. What is Thermal-Transfer? - Knowledge Base Thermal-transfer printing uses a ribbon to print information on labels. The heated print-head is used to melt the ink coating of the ribbon, transferring it to the label. Since the label itself is not reactive, the print produced by this method is much more stable and a lot more durable. The ribbon is typically composed of either resin or wax, or a combination of the two.

Types of Label Printers - The Label Experts Thermal transfer (TT) types of label printers are the industry's choice for high-quality, long-lasting labels. TT printers can range from low cost, entry-level desktop models (such as the Zebra GK420t or the TTP-245C_Series to industrial-grade, continuous printing systems. The latter are used in professional, high volume settings. Types of Labels - A Thomas Buying Guide Thermal transfer labels are used for applications where a direct thermal label is inadvisable, perhaps because the labeled product will be stored close to a heat source. Thermal transfer printing uses a ribbon that prints a long-lasting image or words on a label. A thermal printhead applies heat, melting the ribbon's ink onto the material. Label Definitions and Terms | Perforated Label - I.D. Images Thermal Transfer: a material that requires a thermal transfer ribbon for printing. Heat is applied to the ribbon which transfers the ink onto the labels. Ideal for products that need more temperature resistance and a longer shelf life than a standard direct thermal product. Label Printing: Important Terms and Definitions | The Label Printers The process of raising a design or image above the label surface, adding another design element to the finished label. It often uses a set of matched rollers to create the desired effect. Embossing Tip: Embossed and debossed textures can give your label a premium feel. It works well for luxury products such as fine wines and perfumes. Engraving

Industrial 4" Thermal EX4T2-HS 104mm Thermal transfer or direct thermal Label Printer 300dpi ...

Polypropylene (BOPP) Labels - Everything You Need To Know These thermal BOPP labels would come in one of two formats: Direct Thermal (no ribbon) or Thermal Transfer (ribbon required). The advantage of Direct Thermal labels is they do not require a ribbon to print. This means that you only need to inventory one supply item, as opposed to the two required for Thermal Transfer. Although these Direct ...

Home - TTP - Thermal Transfer Products Thermal Bypass Valve. An optional feature for the MAR and BOLR Series - thermal bypass and pressure relief features combined in one valve. Temperature bypass is activated (closes) when oil reaches a defined set point of 110° F and allows full oil flow through the heat exchanger. When the oil is cool, the valve is open to allow a partial flow ...

Thermal Ribbons — Thermal Label Warehouse LLC Premium resin thermal transfer ribbons are excellent for printing on coated papers and synthetic materials for harsh environments. Our resin ribbons print at high speeds with higher resolutions all while offering superior scratch and chemical resistance. Recommended substrates include coated paper and materials, polyester, polypropylene, nylon ...

Direct Thermal Labels vs Thermal Transfer Labels difference ... 30 Dec 2019 — Thermal transfer labels are used for the thermal transfer printer. The print head applies heat to the ribbon, which melts either wax or a ...

Thermal Transfer vs. Direct Thermal: Five Key Considerations Direct thermal printing requires the print head elements be in direct contact with the label material as it is pulled across the print head. Conversely, thermal transfer printing has thermal ribbon acting as a "buffer" between the print head elements and the label material.

Thermal Transfer Labels - Data Label, Inc. Thermal Transfer Labels. A thermal printhead applies heat to thermal ribbon. The ribbon is then pressed and absorbed into the label paper to create the printed label. ... 1-1/2″ x 1″ Thermal Transfer | 3″ Core 620-STT-15-1 View Product Details; Sale! 3″ x 2″ Perforated Fanfolded Thermal Transfer 820-TT-3-2PF View Product Details;

Thermal-transfer printing - Wikipedia Thermal transfer is a popular print process particularly used for the printing of identification labels. It is the most widely used printing process in the world for the printing of high-quality barcodes. Printers like label makers can laminate the print for added durability. Thermal transfer printing was invented by SATO corporation.

Label Adhesives Guide: Types and Properties | Label Printing Permanent: The majority of labels we print use a permanent adhesive because they work for most label applications and tend to be the most budget-friendly. Since permanent adhesive labels create a strong bond with the container they are applied to, removing the label can damage the label or container. Removable: Labels with a removable adhesive ...

Post a Comment for "43 thermal transfer labels definition"